In the world of aviation, safety remains the paramount concern for pilots and passengers alike.

Among the critical procedures ensuring a safe flight is the aircraft pre-flight inspection, a thorough examination performed before every takeoff.

But, what exactly does an aircraft pre-flight inspection entail, and why is it so vital?

An aircraft pre-flight inspection is not just a routine check; it’s a systematic assessment to uncover any potential issues that might compromise the flight’s safety.

It’s a pilot’s chance to familiarize themselves with the aircraft’s condition before flight.

Unveiling the Significance of Aircraft Pre-Flight Inspections

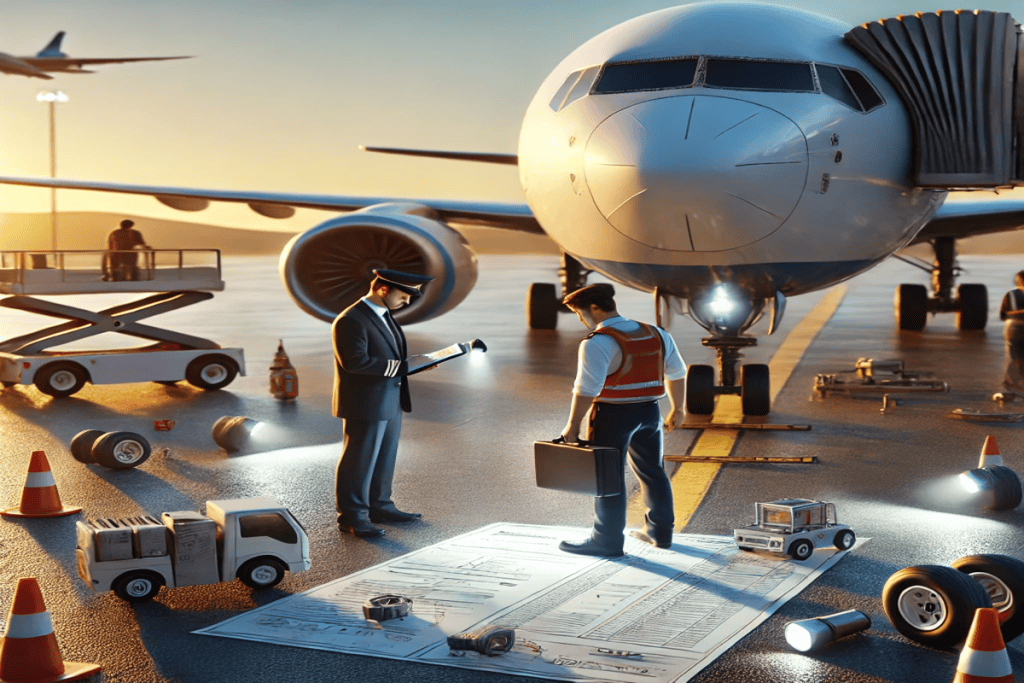

Imagine this: you’re about to embark on a long-awaited journey, and as you approach the aircraft, you witness a flurry of activity.

Ground crew members scurry about, pilots circle the plane, their eyes scanning every inch.

This scene, far from being a cause for concern, signifies a commitment to safety – it’s the aircraft pre-flight inspection in action.

Why is Aircraft Pre-Flight Inspection Crucial?

Aircraft inspections are vital for multiple reasons.

Most importantly, these inspections help identify any maintenance issues before they escalate into in-flight problems.

This includes checking for things like fuel leaks, tire wear, or cracks in the aircraft structure.

By spotting these issues early, potential accidents can be avoided.

Additionally, pre-flight checks confirm that the aircraft complies with all safety regulations.

Just like a car needs regular maintenance checks to ensure roadworthiness, an aircraft pre-flight inspection ensures it’s ready to take to the skies.

Who Performs Aircraft Pre-Flight Inspections?

While specific procedures may differ between airlines and aircraft types, the primary responsibility for an aircraft pre-flight inspection typically lies with the pilot in command.

This pilot is known as the Pilot in Command (PIC).

The PIC meticulously inspects the aircraft’s exterior, interior, and systems.

In some cases, qualified aircraft maintenance technicians might assist with specific checks, especially after maintenance work.

Regardless of who performs which part of the check, every detail is vital to ensuring a safe journey.

The PIC will use a written checklist during this process to ensure they do not miss anything.

Delving Deeper into the Process

Now that you understand the “why”, let’s explore the “how”.

The aircraft pre-flight inspection is a meticulous, multi-faceted process.

A well-defined checklist, specific to each aircraft type, ensures that nothing is overlooked.

Visual Inspections: A Comprehensive Exterior Assessment

The inspection begins with a visual assessment.

As the PIC walks around the aircraft, they carefully examine the exterior.

They look for any visible damage, leaks, or obstructions.

A flight instructor will go over all of these procedures with a student as part of their flight school training.

Key areas of focus include:

- Fuselage: This involves inspecting the aircraft’s main body for any dents, cracks, loose panels, or signs of corrosion. Imagine, a small, overlooked crack could expand during flight due to the immense pressure changes, leading to potential danger.

- Wings: Each wing is scrutinized for damage, particularly the leading edges and wingtips. Damaged wings could lead to a crash. A visual check of the flaps and ailerons is done to confirm they move freely. A simple thing like bird damage from a previous flight could severely impact aerodynamic performance during takeoff or landing.

- Empennage: The tail section undergoes similar scrutiny. This area houses the vertical stabilizer and rudder, which are crucial for controlling direction. Issues here could make maneuvering difficult. The control surface here needs to be inspected for any material damage. Any composite materials damage could impact flight.

- Landing Gear: Tires are checked for pressure and wear, ensuring they can handle the impact of landing. This part of the inspection also confirms that brakes and hydraulic lines are free from leaks. The gear struts are also inspected to ensure they are in safe operational condition.

Venturing Inside the Aircraft

After the external inspection, the pre-flight inspection continues inside the aircraft.

The interior inspection might not seem as outwardly exciting as checking for wing damage but is no less important.

The PIC inspects essential systems:

Before even getting inside the cockpit, the PIC will open various panels on the aircraft to visually check the components for any visible problems.

One of the things they are looking for here is if there is proper oil levels.

The fuel tanks will also be visually checked for the fuel quantity in each.

They will then check the fuel gauges to ensure the reading matches what they saw in the tanks.

Once in the cockpit, here are some of the things they will check:

- Fuel Levels: This involves checking the amount of fuel onboard and ensuring the fuel is free from water or contaminants. Accurate fuel assessment is paramount. A misunderstanding here could even lead to the unthinkable – fuel exhaustion mid-flight.

- Oil Levels: Like with a car, checking engine oil is critical. Low oil can indicate a leak or engine issues that require attention before takeoff.

- Hydraulic Systems: Many aircraft systems, including the brakes, landing gear, and flight controls, rely on hydraulics. The PIC makes sure fluid levels are adequate and there’s no sign of leakage.

- Emergency Equipment: This step ensures that safety equipment is present and functional. Oxygen masks, life jackets, fire extinguishers, and first aid kits need to be ready for immediate use. These precautions are vital because, while we all hope for smooth sailing, preparedness for unforeseen events is crucial.

- Cockpit Switches: All the switches in the cockpit are inspected to ensure they are in the correct position and function correctly.

- Control Surfaces: Inside the cockpit, the control surfaces are checked again. This is to ensure that when the pilot moves a control, the corresponding control surface on the aircraft’s exterior also moves. For example, moving the yoke should move the ailerons.

Verifying the Documentation: A Critical Review

Before taking to the skies, the pilot undertakes a crucial final step in the aircraft pre-flight inspection process: a meticulous review of all necessary documents.

Imagine a detective carefully piecing together clues; this final stage confirms everything is in order for a legal and safe flight.

Here’s what’s included:

- Airworthiness Certificate: This document is like the aircraft’s birth certificate, verifying that it was built and maintained according to approved standards. A valid certificate means the aircraft meets all safety standards. The airworthiness certificate will list the aircraft serial number.

- Registration: Like car registration, this shows who owns the aircraft and allows it to operate legally.

- Logbooks: Logbooks document all maintenance, repairs, and inspections the aircraft has undergone. Reviewing the logs lets the pilot understand recent work done and any recurring issues. It’s crucial to review maintenance logs because a missed entry might indicate a necessary safety check was overlooked. The PIC is looking for any open maintenance issues that would prevent the aircraft from being able to legally fly.

- Radio Station License: Like a radio station, an aircraft needs a station license to transmit and receive radio communications. This license confirms the aircraft’s radio equipment meets regulatory standards.

- Pilot Operating Handbook: The Pilot Operating Handbook, or POH, is the aircraft’s instruction manual. It contains vital information about the aircraft’s systems, limitations, and emergency procedures. Pilots use the POH for a comprehensive understanding of the specific aircraft they are flying.

- Operating Limitation Documents: This documentation outlines any specific limitations or restrictions for the particular aircraft, such as maximum weight limits or specific weather conditions the aircraft isn’t allowed to fly in.

- Type Certificates: Issued by aviation authorities like the Federal Aviation Administration (FAA) in the US, type certificates verify that a particular aircraft design meets airworthiness standards.

- Airworthiness Directives: These are legally enforceable regulations issued by aviation authorities to address safety concerns. Pilots and maintenance personnel must check for and comply with any applicable airworthiness directives to ensure continued operational safety.

- Supplemental Type Certificates: These certificates approve modifications or major repairs made to an aircraft after its original certification. The PIC needs to make sure any modifications have the appropriate documentation.

Wrapping Up

An aircraft pre-flight inspection, although seemingly mundane from a distance, represents a fundamental pillar of aviation safety.

It’s not just about ticking boxes on a checklist, it’s about vigilance, responsibility, and an unwavering dedication to ensuring that every flight takes off with the highest chance of reaching its destination safely.

Even something small like a cotter pin can cause big problems.

During the inspection, they will be checking things like this to make sure it is all in place and safe.

Through a comprehensive aircraft pre-flight inspection, pilots create the foundation for security control and an enjoyable flying experience for all.

Remember, next time you settle into your seat and prepare for takeoff, that flurry of activity you witnessed was all part of a well-choreographed routine, prioritizing your safety.

FAQs About Aircraft Pre-Flight Inspection

Do pilots inspect planes before every flight?

Yes, an aircraft pre-flight inspection happens before every single flight without exception.

Think of it as a non-negotiable ritual, much like buckling your seatbelt.

The consistency of these checks ensures that no matter how short the flight or how experienced the pilot is, the same meticulous attention to safety is always applied.

How long does a pre-flight check take on a plane?

While the duration can vary, a thorough aircraft pre-flight inspection can take anywhere between 30 to 60 minutes or more.

This will depend on if the aircraft is a small general aviation aircraft, or a large passenger aircraft.

The PIC is also looking for any foreign objects that should not be there.

Other things that add to the complexity are the aircraft’s size, the number of systems needing examination, and any recent maintenance conducted.

Think of it as an investment – those minutes on the ground ensure hours of safety in the air.